Custom Plastic Tubing: Precision Extrusion for Diverse Applications

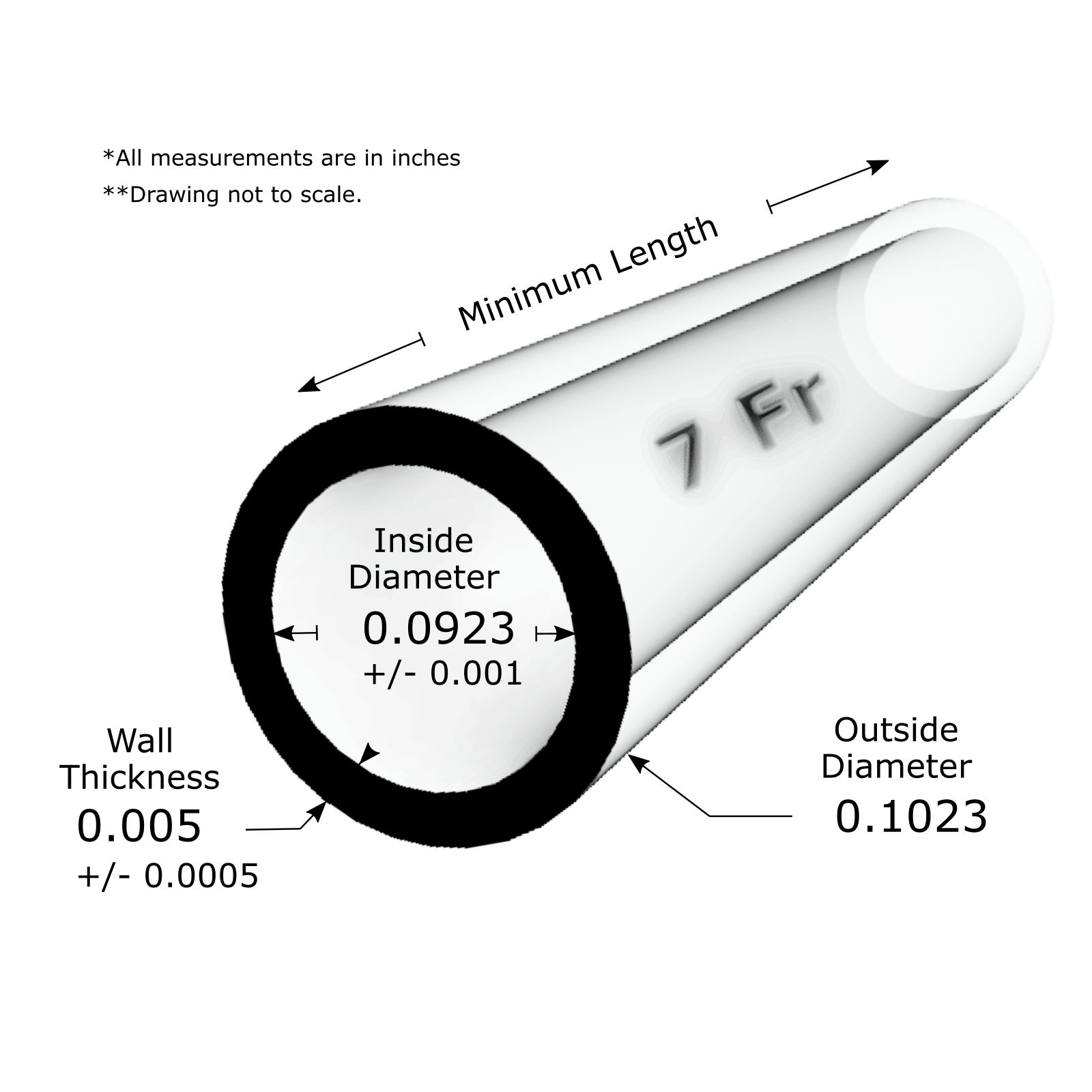

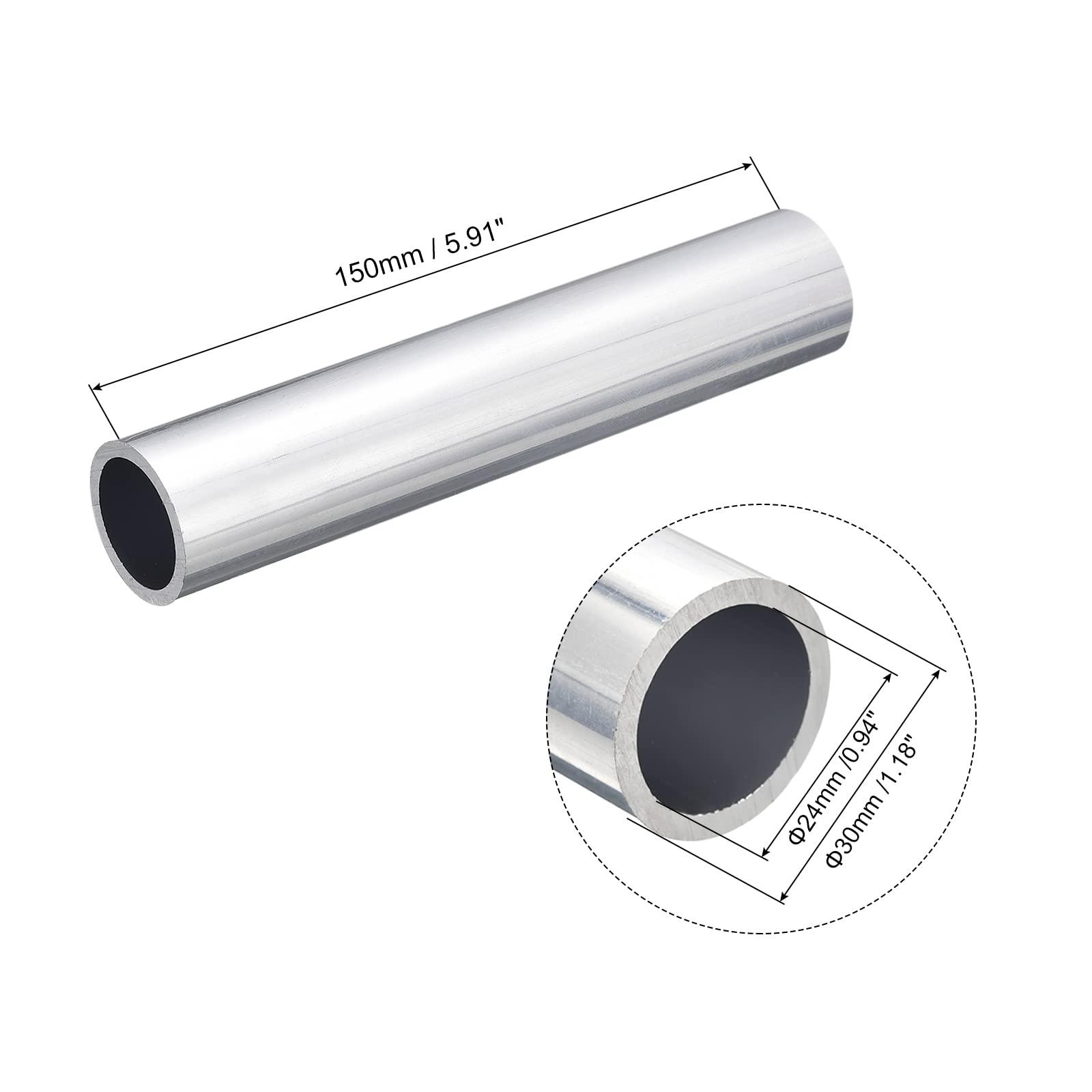

Precision custom plastic tubing requires accurate Outer Diameter (OD), Inner Diameter (ID), and wall thickness specifications.

We extrude flexible plastic tubing in a wide range of custom colors to meet your specific application or branding needs.

From clear PVC to colored polyethylene, our plastic extrusion process handles diverse materials for any industry.

At GSH Industries, we specialize in custom plastic tubing that is precision-engineered to meet the needs of a variety of industries. Whether you're looking for durable tubing for automotive, medical, industrial, or consumer applications, we offer a range of solutions designed for superior performance, flexibility, and durability. This paragraph will wrap around the floated image if it's long enough.

Our custom plastic tubing extrusion process ensures tight tolerances, high consistency, and versatility in size and shape. We work with a wide range of materials to produce tubing that meets your exact specifications, from simple designs to complex multi-layer solutions. More text here to demonstrate wrapping. If the image is taller than these first paragraphs, subsequent paragraphs will also wrap.

This is another paragraph that will continue to flow around the image if space allows. The text wraps neatly to the left of the floated image container. We've given the container a specific width, padding, and some margins for spacing.

Popular Applications of Custom Plastic Tubing

- Medical Devices: Biocompatible tubing for fluid delivery, oxygen therapy, and surgical applications.

- Automotive: Tubing for fuel lines, brake systems, and electrical conduits, resistant to chemicals and heat.

- Industrial Applications: Used in fluid transport, hydraulic systems, and harsh environments.

- Food and Beverage: FDA-approved tubing for processing and production lines.

- Consumer Goods: Tubing for electronics, toys, home appliances, and more.

Stock Tubing Available!

| Outer Diameter (OD) | Inner Diameter (ID) | Wall Thickness | Material | Colors Available |

|---|---|---|---|---|

| 1/8" | 1/16" | 1/32" | PVC, Polyethylene | Black, White |

| 1/4" | 3/16" | 1/32" | PVC, Polypropylene | Black, White |

| 3/8" | 1/4" | 1/16" | ABS, Polyethylene | Black, White |

| 1/2" | 3/8" | 1/16" | Polypropylene, PVC | Black, White |

| 3/4" | 5/8" | 1/16" | ABS, Polypropylene | Black, White |

| 1" | 7/8" | 1/8" | PVC, Polyethylene | Black, White |

| 1-1/4" | 1" | 1/8" | PVC, ABS | Black, White |

| 1-1/2" | 1-1/4" | 1/8" | Polyethylene | Black, White |

| 2" | 1-3/4" | 1/8" | Polypropylene, PVC | Black, White |

| 2-1/2" | 2-1/4" | 1/8" | PVC, ABS | Black, White |

Stock lengths: 8 feet.

Materials We Work With for Custom Plastic Tubing

- PVC (Polyvinyl Chloride): Lightweight and chemical-resistant, great for general-purpose use.

- PE (Polyethylene): Flexible and durable, suitable for hydraulic systems and fluid transport.

- Nylon (Polyamide): Strong and resistant to chemicals, ideal for demanding industrial uses.

- Silicone: FDA-approved, flexible, and resistant to extreme temperatures.

- Custom Blends: Formulations for UV resistance, flame retardance, or anti-static properties.

Custom Tubing Specifications

- Diameter: 0.125" to over 6".

- Wall Thickness: 0.020" to 1.5".

- Length: Custom cut or coiled for convenience.

- Tolerances: As tight as ±0.002" for precision.

Why Choose GSH Industries for Custom Plastic Tubing?

- Expert Engineering: Experienced team across various industries.

- Precision Manufacturing: Advanced extrusion for consistent quality.

- Material Flexibility: Wide range of materials from PVC to PTFE.

- Tailored Solutions: Custom sizes, shapes, and materials.

- Custom Lengths & Sizes: Flexible for both large and small runs.

Contact Us Today for Custom Plastic Tubing Solutions

Looking for a custom plastic tubing extrusion solution for your project? At GSH Industries, we are committed to delivering high-quality tubing with precision and flexibility. Contact us today to discuss your requirements and discover how we can help you achieve the best results.

Contact us today to learn more about our custom plastic extrusions and discover how we can help meet your project’s needs with unparalleled expertise.