Unleash the Power of Plastic Extrusions with GSH Industries.

Plastic extrusions are the silent workhorses of countless industries, shaping diverse products from window frames to medical tubing. At GSH Industries, we have mastered the art of plastic extrusion, transforming raw materials into precise, high-performance shapes that fuel your vision.

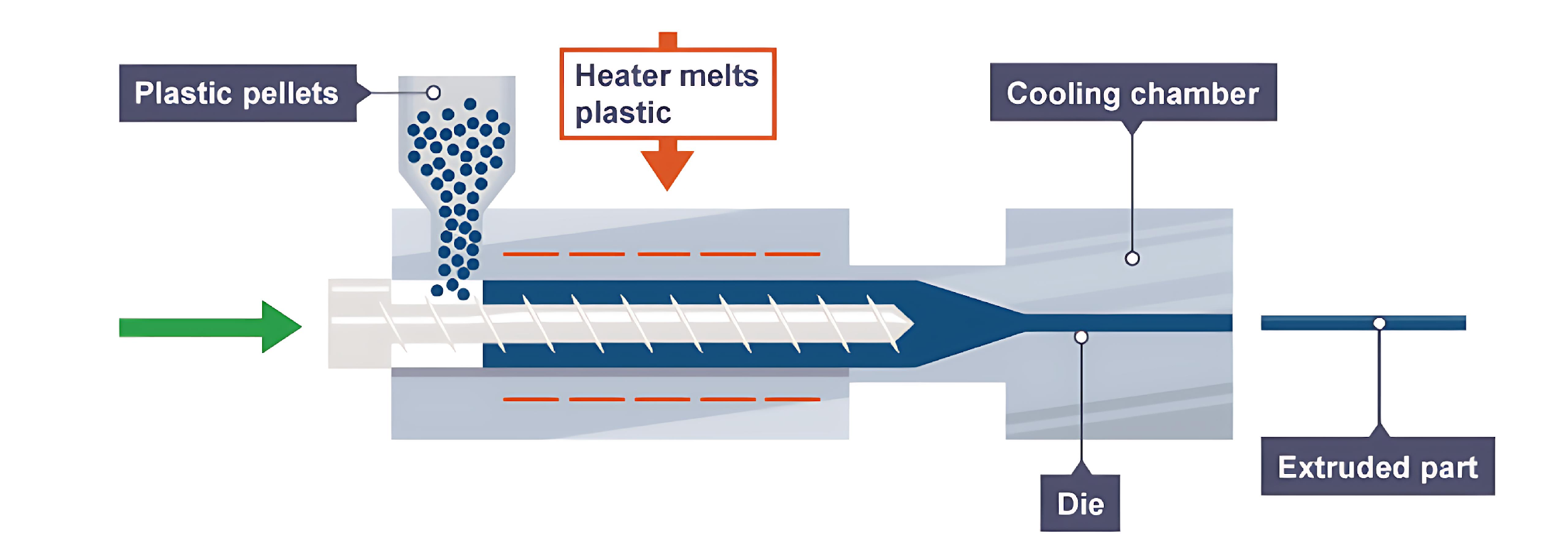

What are Plastic Extrusions?

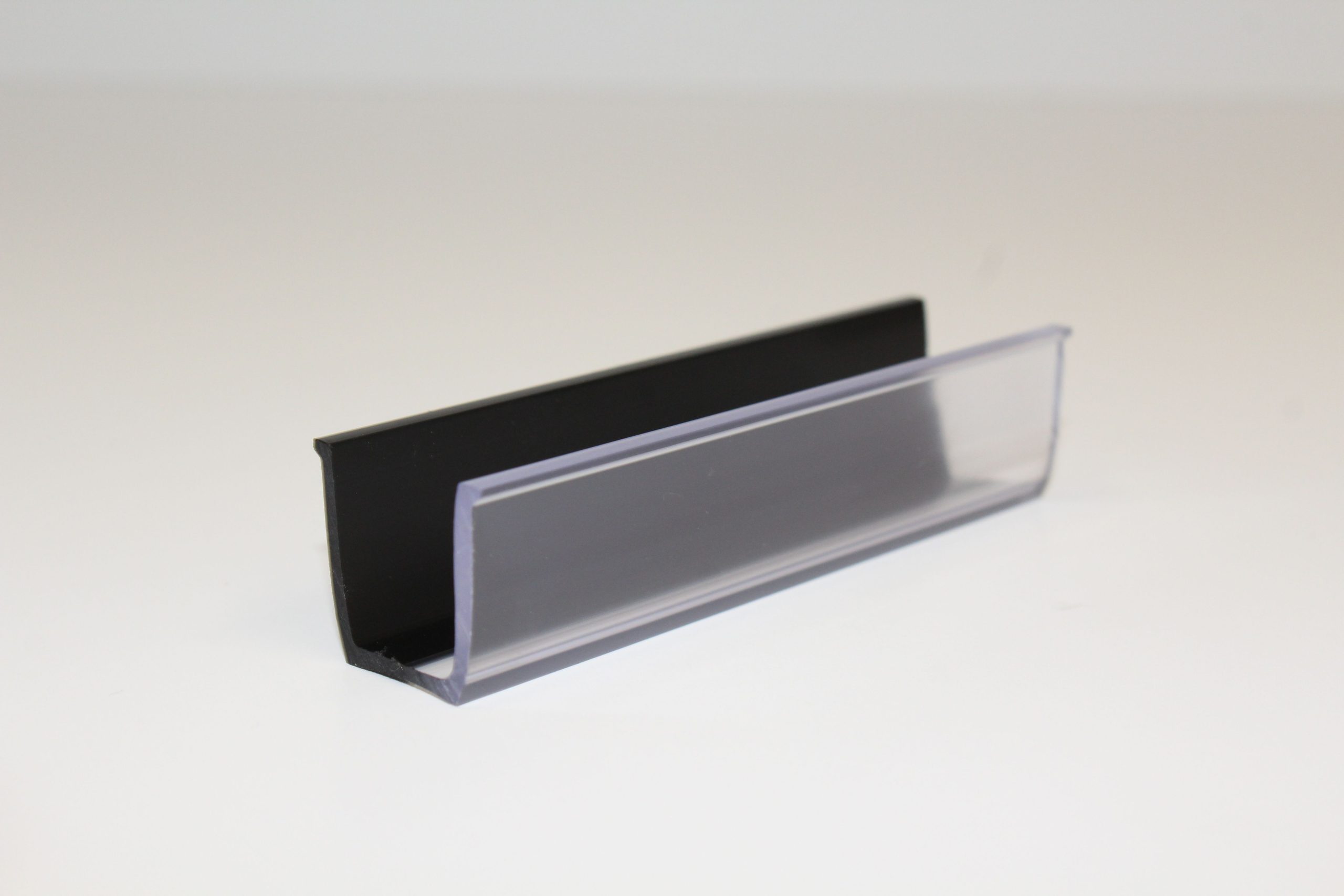

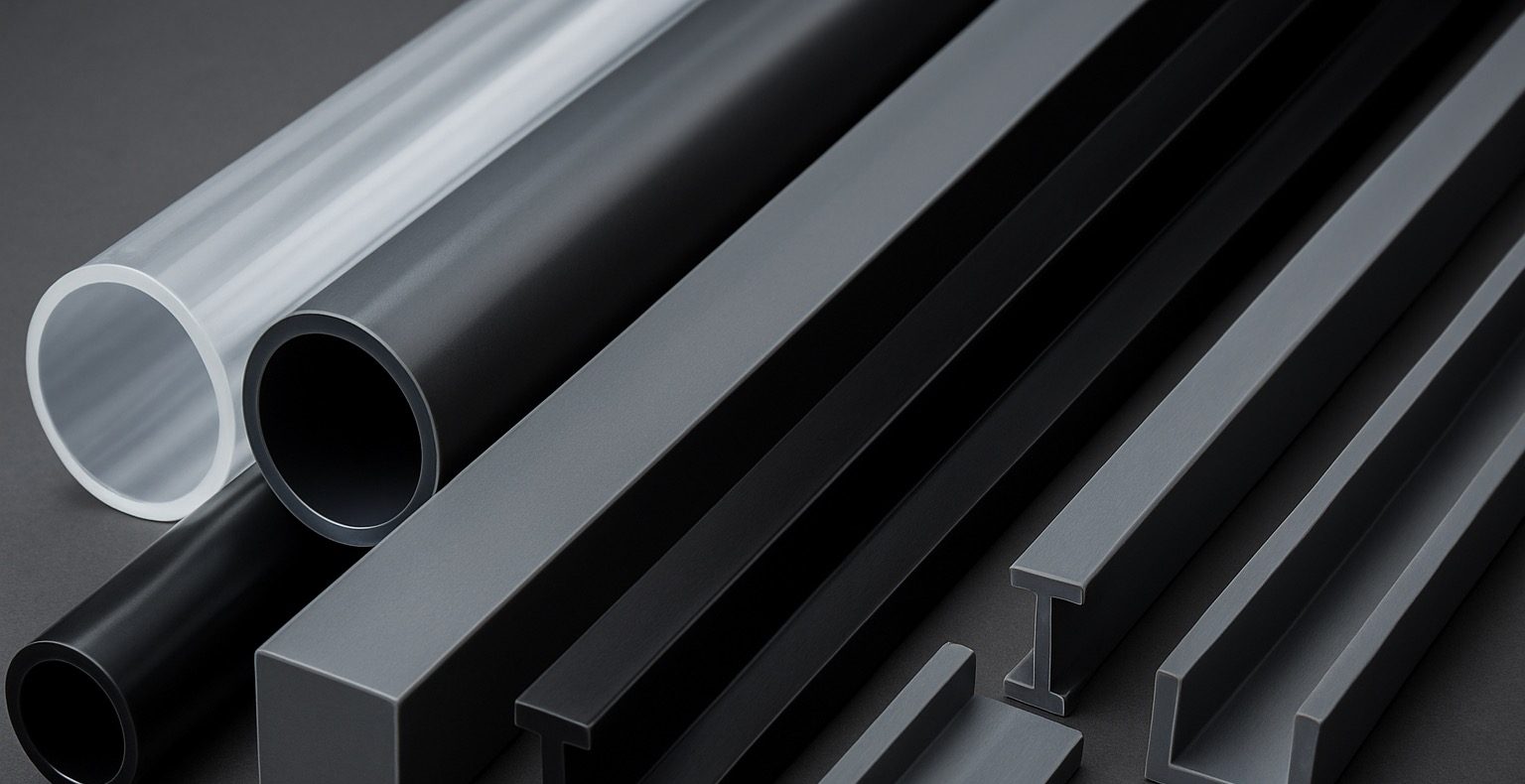

Plastic extrusion is a continuous manufacturing process where molten plastic is forced through a shaped die, creating long, continuous profiles with consistent cross-sections. These profiles, available in various shapes, sizes, and materials, offer unmatched versatility and functionality.

Why Choose GSH Industries for Your Plastic Extrusions Needs?

Unmatched Expertise: With over 30 years of experience, our team possesses the in-depth knowledge and technical skills to tackle any extrusion challenge.

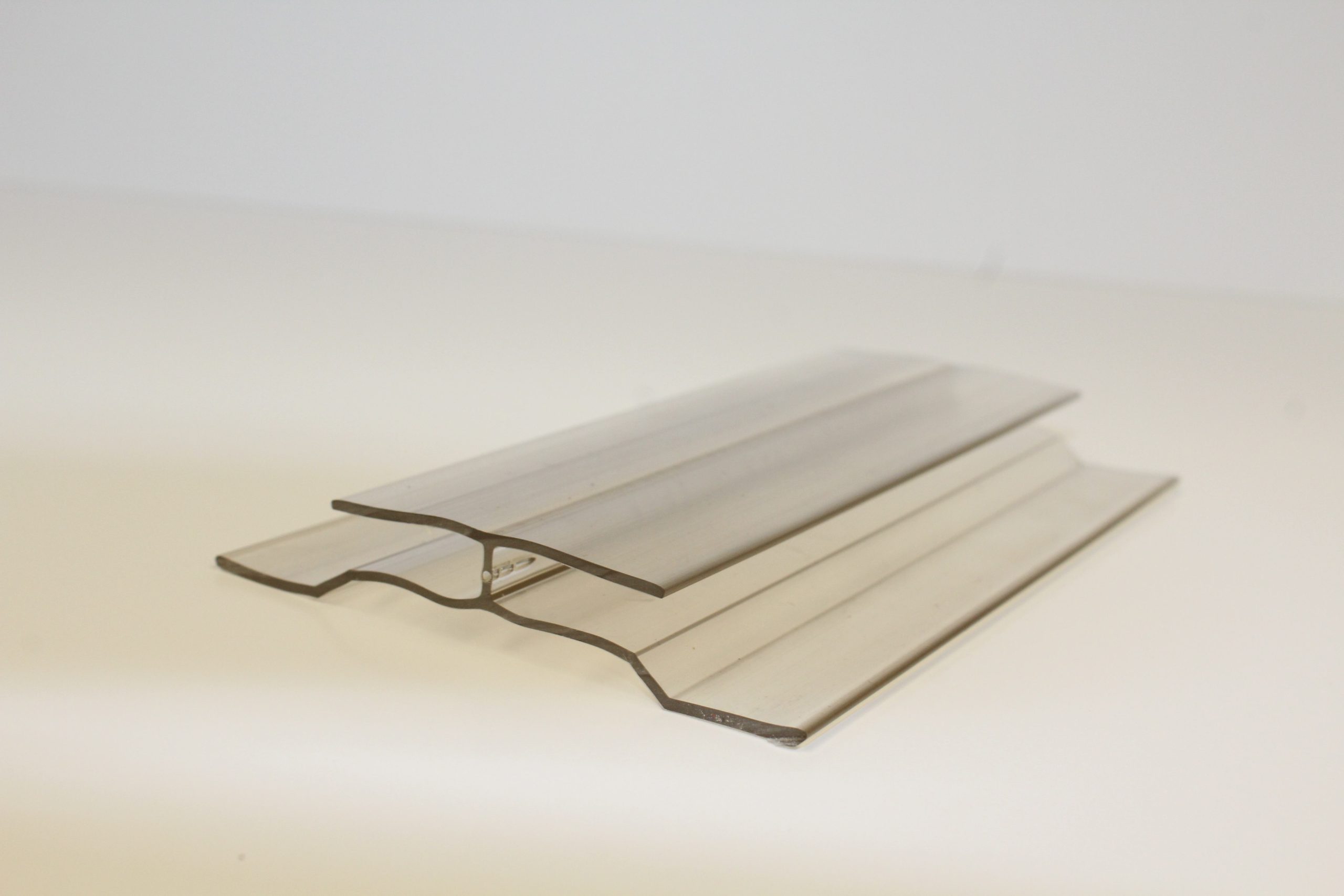

Extensive Material Selection: We offer a vast array of plastic materials, including PVC, ABS, Polycarbonate, Nylon, Noryl, Hytrel and more, each with unique properties suited for specific applications.

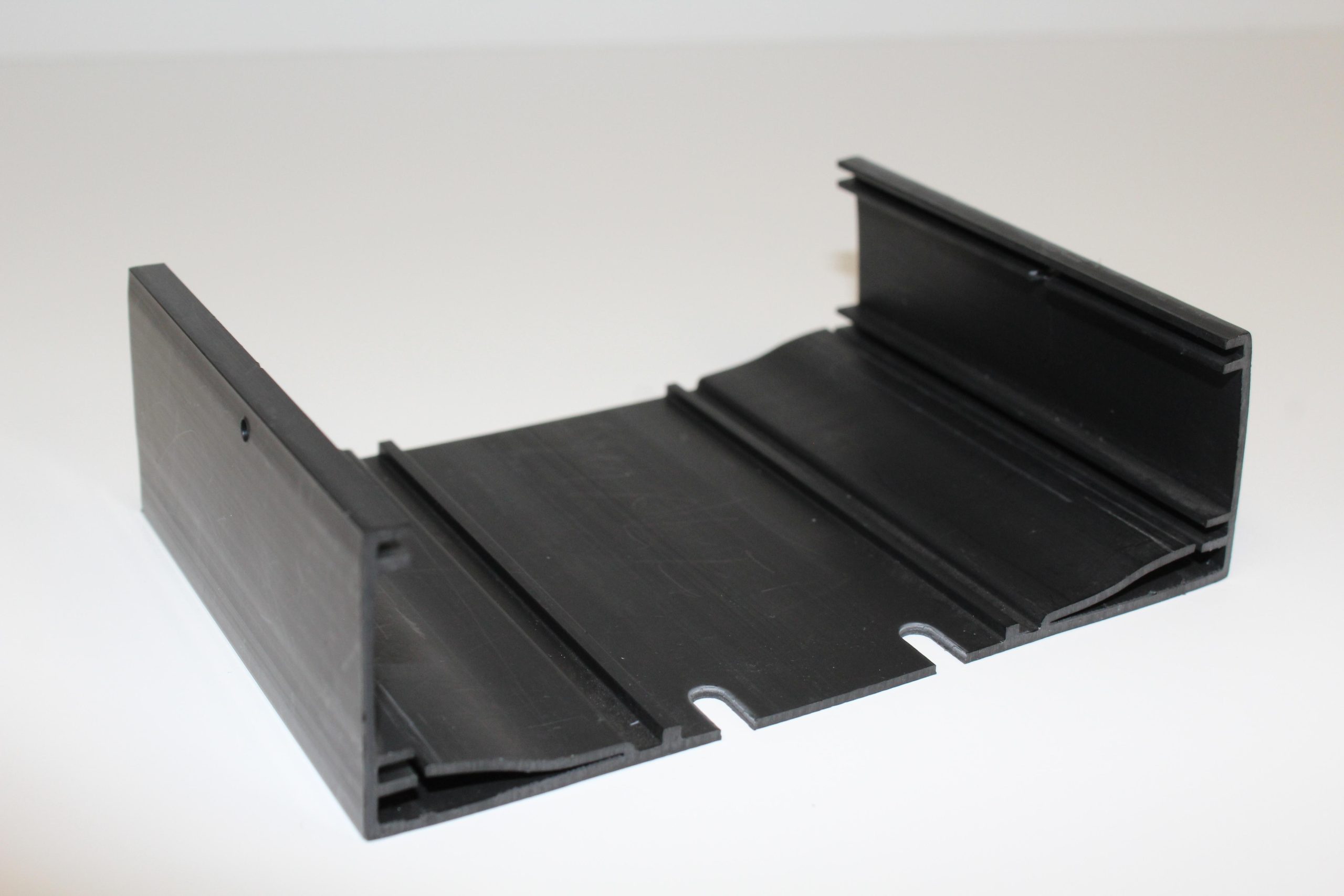

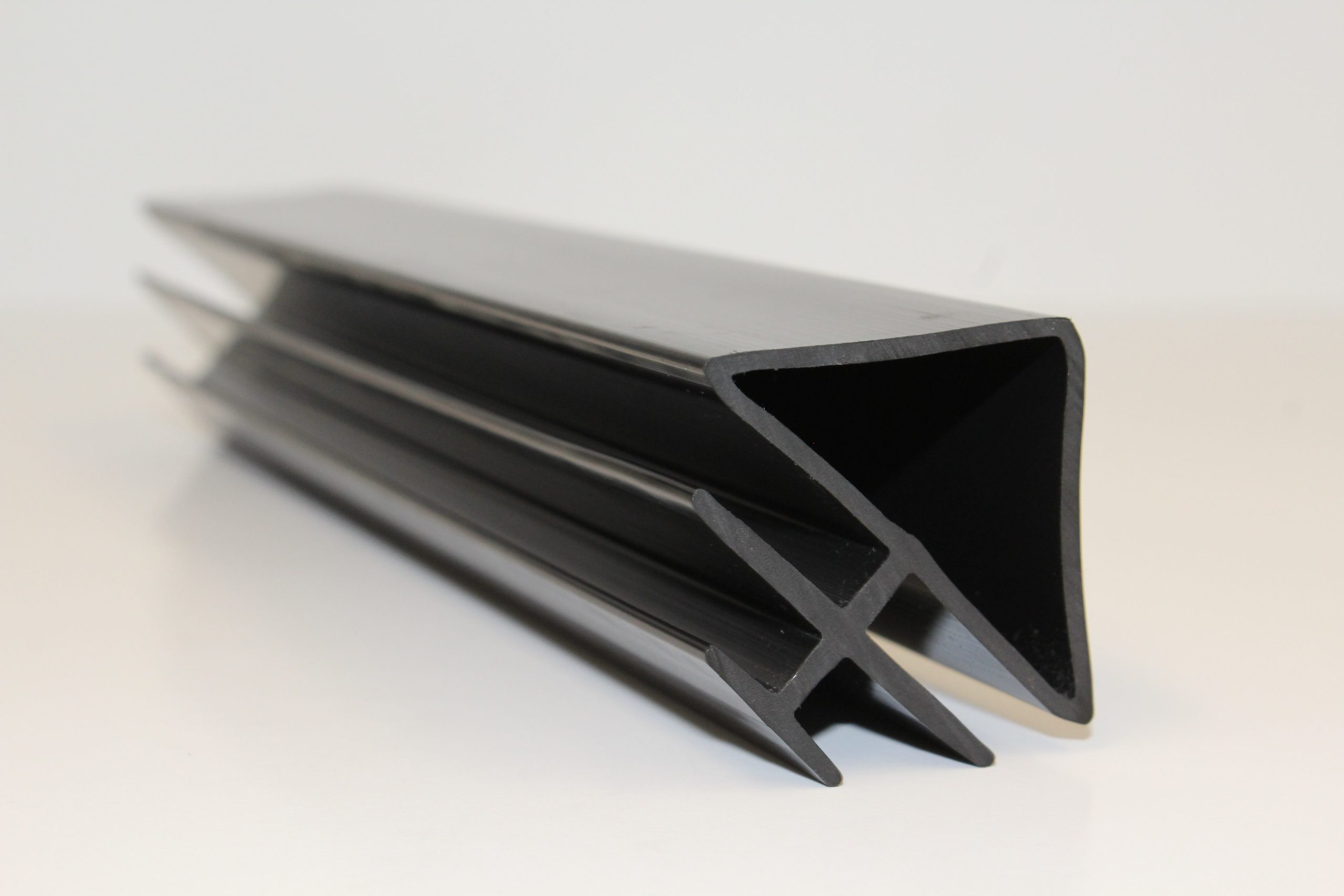

Customizable Solutions: Our capabilities extend far beyond stock extrusions. We excel at custom profiles, tailoring designs to your precise requirements and specifications.

Stringent Quality Control: We adhere to rigorous quality control measures, ensuring every extrusion meets your exact standards and delivers optimal performance.

Value-Added Services: From prototyping and design assistance to secondary fabrication and finishing, we provide a comprehensive suite of services to streamline your project.

Benefits of Plastic Extrusions:

Cost-Effective: Extrusions offer a cost-efficient way to produce large quantities of complex shapes with minimal waste.

Design Flexibility: The vast array of shapes and materials enables limitless design possibilities.

Durability & Longevity: Plastic extrusions are renowned for their strength, weather resistance, and long-lasting performance.

Lightweight & Versatile: Their lightweight nature makes them ideal for diverse applications, from construction to medical devices.

Sustainable Solutions: GSH Industries is committed to sustainable practices, offering eco-friendly material options and minimizing waste throughout the process.

Applications of Plastic Extrusions:

The applications of plastic extrusions are virtually endless, spanning across various industries:

Construction: Window profiles, trim, weatherproofing components, and more.

Automotive: Interior trim, weather seals, hose covers, and other functional parts.

Medical: Tubing for catheters, IV lines, and other medical equipment.

Consumer Goods: Furniture components, appliance parts, packaging materials, and more.

Industrial: Conveyor belts, cable management systems, and various industrial components.

Partner with GSH Industries for Exceptional Plastic Extrusions:

At GSH Industries, we are more than just plastic extrusion manufacturers; we are your trusted partners in bringing your vision to life. Contact us today to discuss your project requirements and experience the GSH difference.